In 2014, the Vale of White Horse District Council commissioned sculptural artist Tim Norris to create a ‘piece of artwork that would bring the community closer together’. Recent building works have seen the small town grow, so it was important to create something which could bring the existing community together with the new.

Tim Norris specialises in large-scale outdoor sculptural works, drawing inspiration from surrounding landscape and where possible uses indigenous natural materials, in combination with recycled or engineered parts.

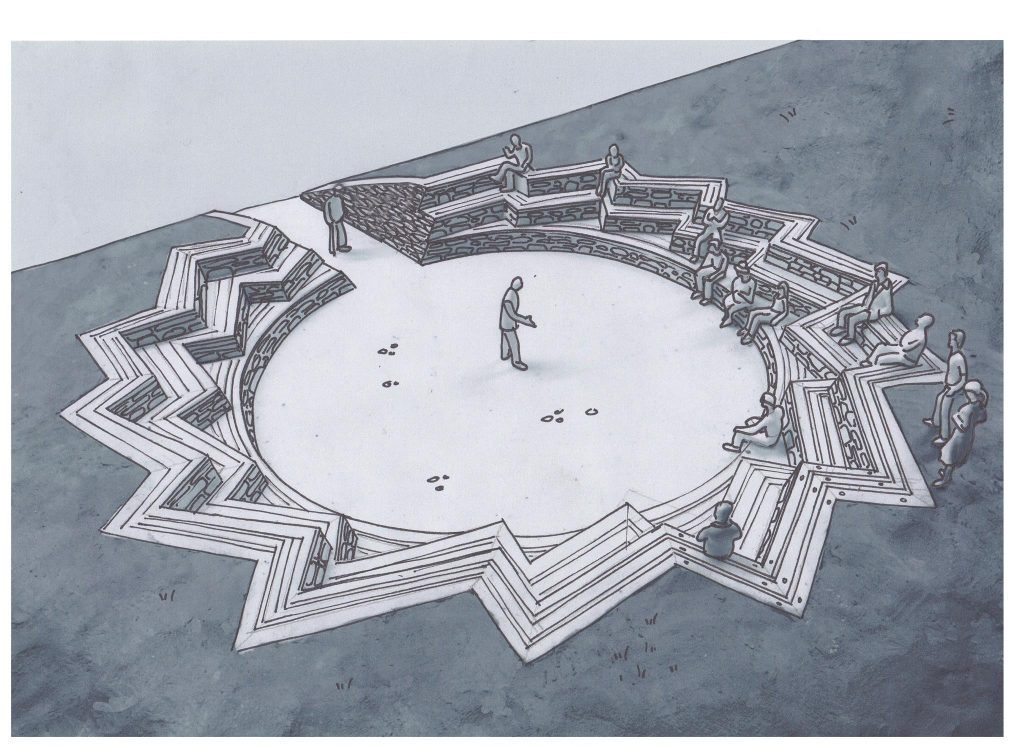

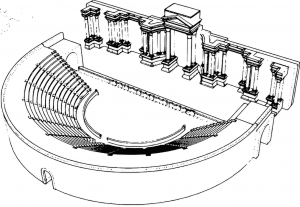

Inspiration for the initial sketch (seen above) was taken firstly from The Ridgeway Path, also known as Britain’s oldest Roman road, which is situated near by and secondly from the Diamond Synchrotron which is a state of the art scientific device at the forefront of modern science and located in Chilton itself. This very modern piece of architecture takes the Roman’s love of socialising and performance on a grand scale and combines it with the internal Zigzag design of the Diamond Synchrotron, meaning that Tim was naturally led to design an traditional amphitheatre with a modern twist. The construction of the project would need precise planning and materials would be carefully selected based on their individual properties.

Inspiration for the initial sketch (seen above) was taken firstly from The Ridgeway Path, also known as Britain’s oldest Roman road, which is situated near by and secondly from the Diamond Synchrotron which is a state of the art scientific device at the forefront of modern science and located in Chilton itself. This very modern piece of architecture takes the Roman’s love of socialising and performance on a grand scale and combines it with the internal Zigzag design of the Diamond Synchrotron, meaning that Tim was naturally led to design an traditional amphitheatre with a modern twist. The construction of the project would need precise planning and materials would be carefully selected based on their individual properties.

Opepe Decking – This dark honey coloured timber is famed for its durability and density.

Maccaferri Gabion’s – These cages are engineered from double twisted hexagonal woven steel mesh. The high quality steel wire is heavily galvanised to provide long term protection from corrosion. However, the cages are only manufactured in squares and for this project rectangles were necessary to create the shape. Tim was able to have these adapted in his studio.

Ardley Limestone – Quarried in the East of Oxfordshire, this limestone is a naturally beautiful but strong and versatile stone.

With the design complete and planning granted, the parish council approached us to see if we would interested in taking part in such a niche project. Having installed some play equipment near by in 2019 we had built a relationship and they knew of our working standards. As soon as we heard about it we were excited to get started, our teams love extraordinary projects like this. As you can see from the images below we began with a blank canvas, with our first job to dig out to make room for the structure inside the existing mound. Next the gabions were brought in and filled with almost 100 tonnes of limestone, an extremely labour intensive job and a lot more precise than you would think. Each stone had to be laid with purpose to create a level top on which the timber was to rest.

To create the smooth curve for the circular lower level the timber had to be subject to a process called Steam Bending, a technique where wood is exposed to steam to make it pliable. Heat and moisture from steam can soften wood fibres enough so they can be bent and stretched, when cooled down they will hold their new shape. A process with astounding results. In total 350m of timber was laid in precise positions at specific lengths to create the stylish seating.

Originally the flooring was to have a country feel, most probably a self binding gravel path however, the final material chosen was Resin bound stone. The blend of rubber and stone creates a more durable, all weather surfacing. With a smoother and cleaner finish, it is less likely to fall victim to vandalism and requires next to no maintenance.